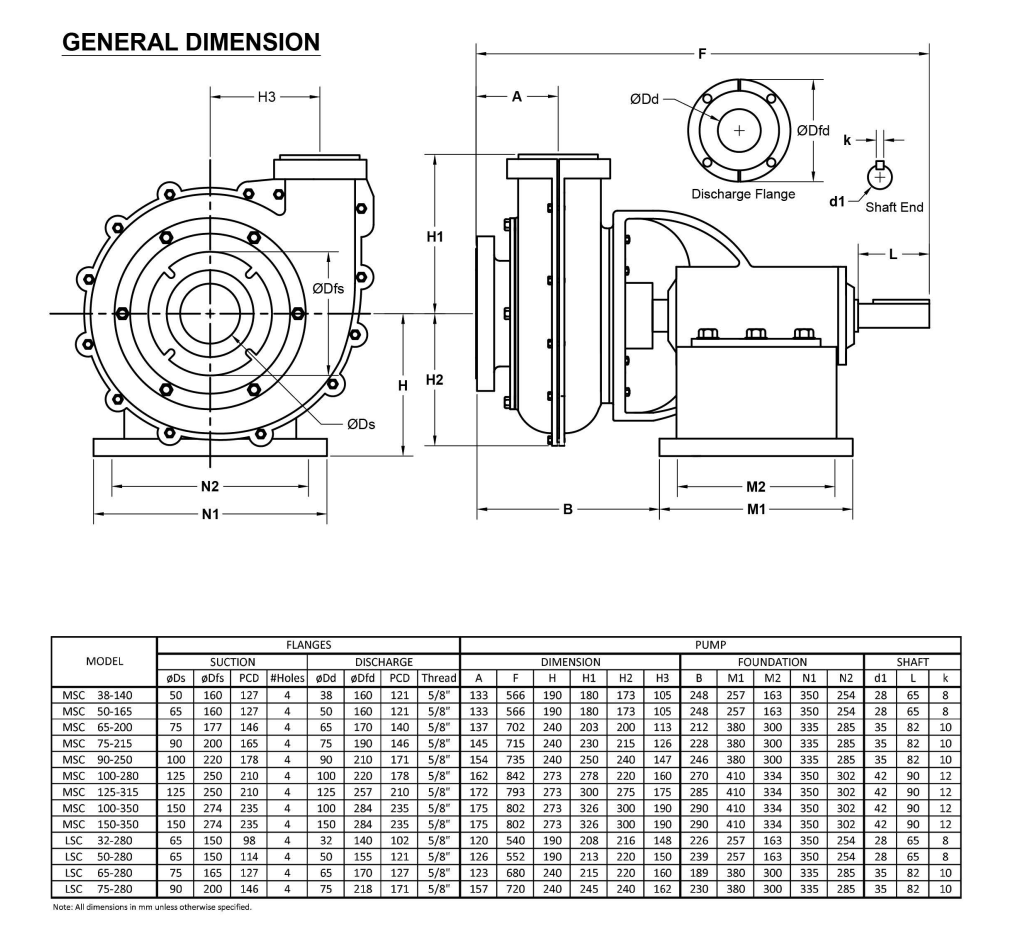

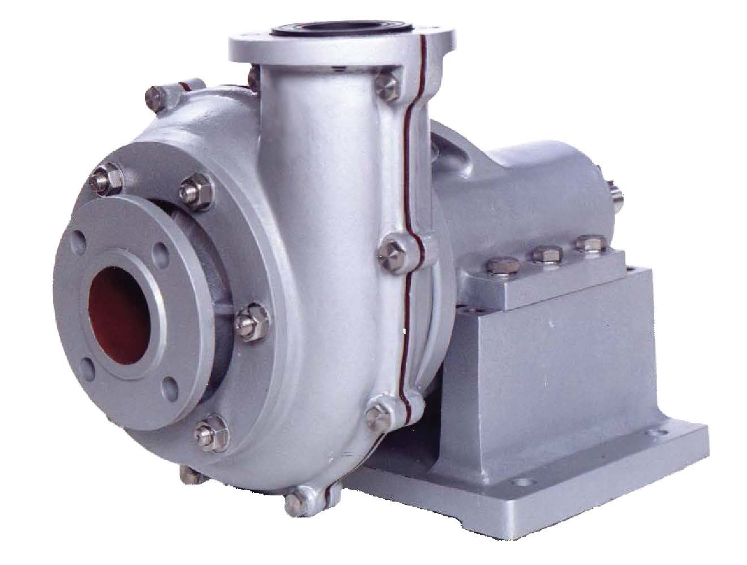

MSC SERIES PUMP

FEATURES

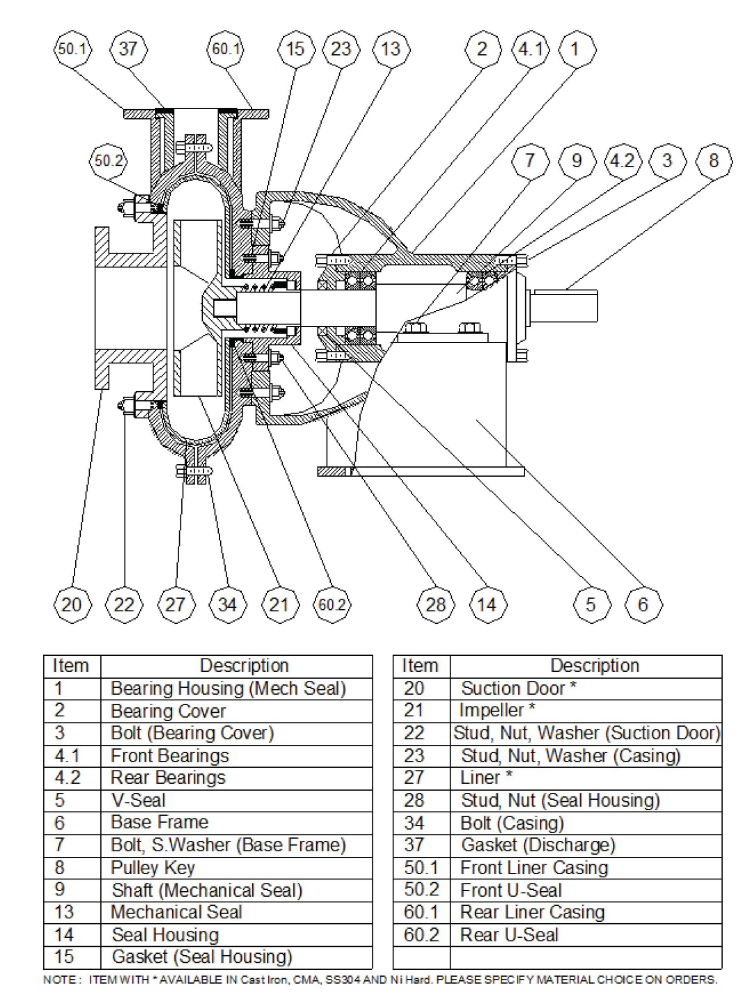

Split casing design with replaceable metal liner. Casing is bolted together, housing the metal liner, with gaskets in between, sealing the pump medium within the liner.

Closed impeller design with wide water passage for excellent solids handling capacity and high working efficiency.

Rotary elements are supported by 4 heavy duty life-lubricated deep groove bearings designed to withstand both the radial and axial loads; results in long service life span and trouble free operation.

Pump shaft is designed with minimal overhang for steadier operation and longer mechani- cal seal life.

Wetted pump parts are available in Cast iron, Ni-hard, Stainless steel and CMA to cater for different pump mediums which can be corrosive, abrasive or a combination of both.

Choice of gland pack or mechanical seal. Different materials in sealing faces are available.

Application

Solid handling

Palm oil mil - Slurry with solid content

Mining - High content of sand stones (often up to 25% by volume)

Minerals - Mineral transfer in the process of separation of different types of mineral.

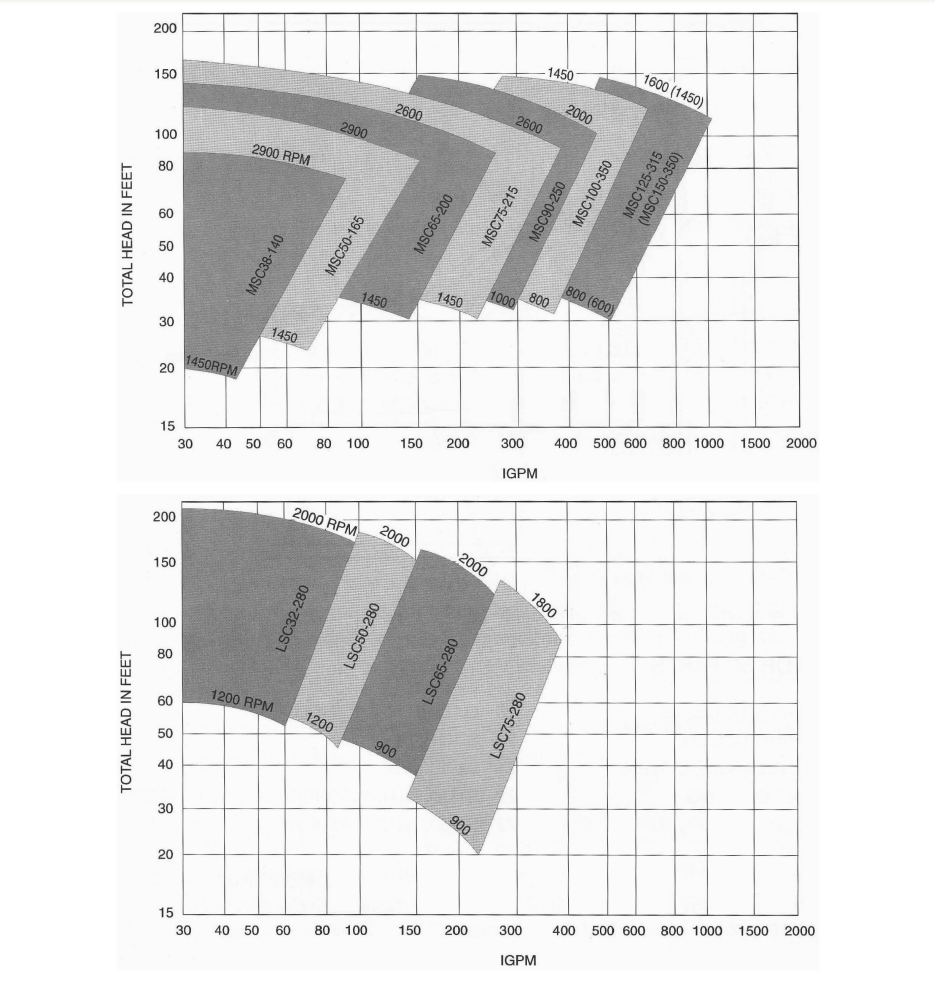

Capacity

-

Up to 500 m3/ hour

-

Up to 75 m Head

-

Operation speed range 600-2900 RPM

-

11 pump sizes

-

4 pedestal sizes

-

Solid handling capacity — up to 70mmB

SPECIFICATION

-

Flange - slotted holes at suction flanges for easy mounting conformity

-

Shaft - in stainless steel or high tensile steel

-

Sleeve - for the protection of shaft (gland packing)

Standard Features

-

Up to 500 m3/ hour

-

Up to 75 m Head

-

Operation speed range 600-2900 RPM

-

11 pump sizes

-

4 pedestal sizes

-

Solid handling capacity — up to 70mmB

Water Box Mechanical Seal

-

SiC vs SiC faces, VITON elastomer, SS316 metal parts as standard.

-

Carbon vs Ceramic faces, BUNA elastomer, SS304 metal parts on request.

Working temperature

-

80°C Max 120°C

Pump End Sealing

-

NBR

Gland Pack

-

Burgmann or equivalent

Bearing

-

4 deep groove life lubricated bearings, SKF or equivalent

Pump End Material Configuration

-

Ni-Hard

-

Stainless Steel

-

Cast Iron

-

CMA